There are 2 fundamental approaches to calculating the inverse kinematics: 1. If you are choosing to create your own inverse kinematic solver, get ready for some serious programming! The Hard Method: Create an Inverse Kinematics Solver If you are using an industrial robot that has come from a robot manufacturer, Option 2 is almost always going to be quicker and easier. If you have built the robot yourself - i.e built it from scratch by connecting motors and mechanical links together - you will likely have to choose Option 1.

Which of these you choose will depend on your unique situation. You can use an existing inverse kinematic solver for your specific robot that works “out of the box.”.You can do all of the mathematical and programming work yourself to create an inverse kinematic solver for your specific robot.However, when we are using robots for industrial applications, there are 2 basic options to find an inverse kinematics solution: Not many people talk about inverse kinematics outside of the research field (except for 3D animators). This is because calculating inverse kinematics is a well-established field in robotics research. When you do some research into inverse kinematics for robotics, you will often find pages and pages of equations, formulas, and algorithm descriptions.

#Kinematics input to postview how to

How to Find the Inverse Kinematics of a Robot Arm This means that there is no simple, direct relationship between the end effector position and any one particular joint.įor example, if you want the robot’s end effector to move 1 mm linearly along the Z-axis, you may need to move all of the joints by a different amount.įinally, inverse kinematics algorithms calculate the exact position of each of the robot’s joints required to reach your desired end effector pose. When you move any one joint, this will affect the end effector’s pose in various ways. The end effector is attached at the end of the entire “kinematic chain”. Each joint is connected to one or more of the other joints, sometimes in complex configurations. Most industrial robots are constructed of several independently controllable articulated joints. When you want your robot’s end effector to move to a particular spot in its workspace, it makes sense that you would input your desired pose into the program.īut, you can’t just tell a robot to go to your desired X, Y, and Z coordinates and expect the robot to understand your instructions… not without inverse kinematics. If we didn’t have inverse kinematics, robot programming would be extremely difficult… if not impossible. Why We Need Inverse Kinematics in Robotics With inverse kinematics, there are often multiple different solutions and multiple approaches to calculating the inverse kinematic solution. When the joints are set to a specific position, the end effector will always end up in the same place. There is only ever one solution to the forward kinematic equation.

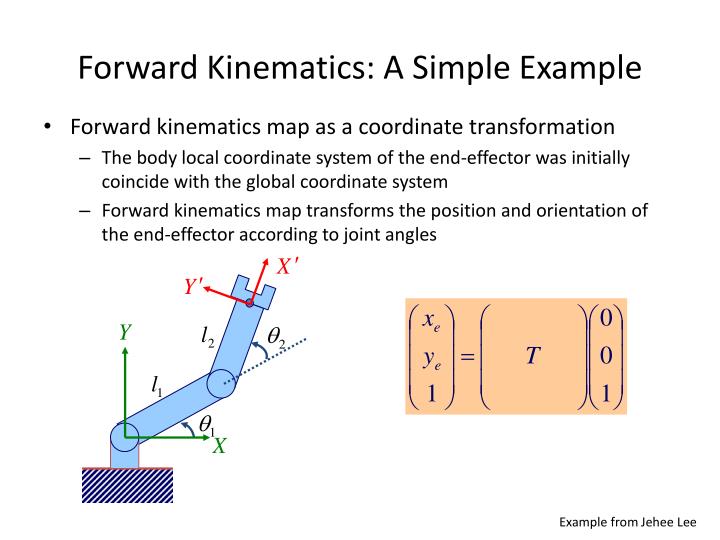

It’s important to be clear about the differences between the inverse kinematics and the robot’s forward kinematics.įorward kinematics determines where the end effector will be if the joints are set to a specific position. A reliable inverse kinematic solution is necessary for programming a robot to perform tasks. Inverse kinematics is a mathematical process used to calculate the joint positions that are needed to place a robot’s end effector at a specific position and orientation (also known as its “pose”). Here is the essential information that you need to know about inverse kinematics for robotics. Depending on your project, you might need to know about it in great detail or get by with basic knowledge. Inverse kinematics for robotics is a huge and often complex topic. How much do you need to know about it to get the most from your robot?

0 kommentar(er)

0 kommentar(er)